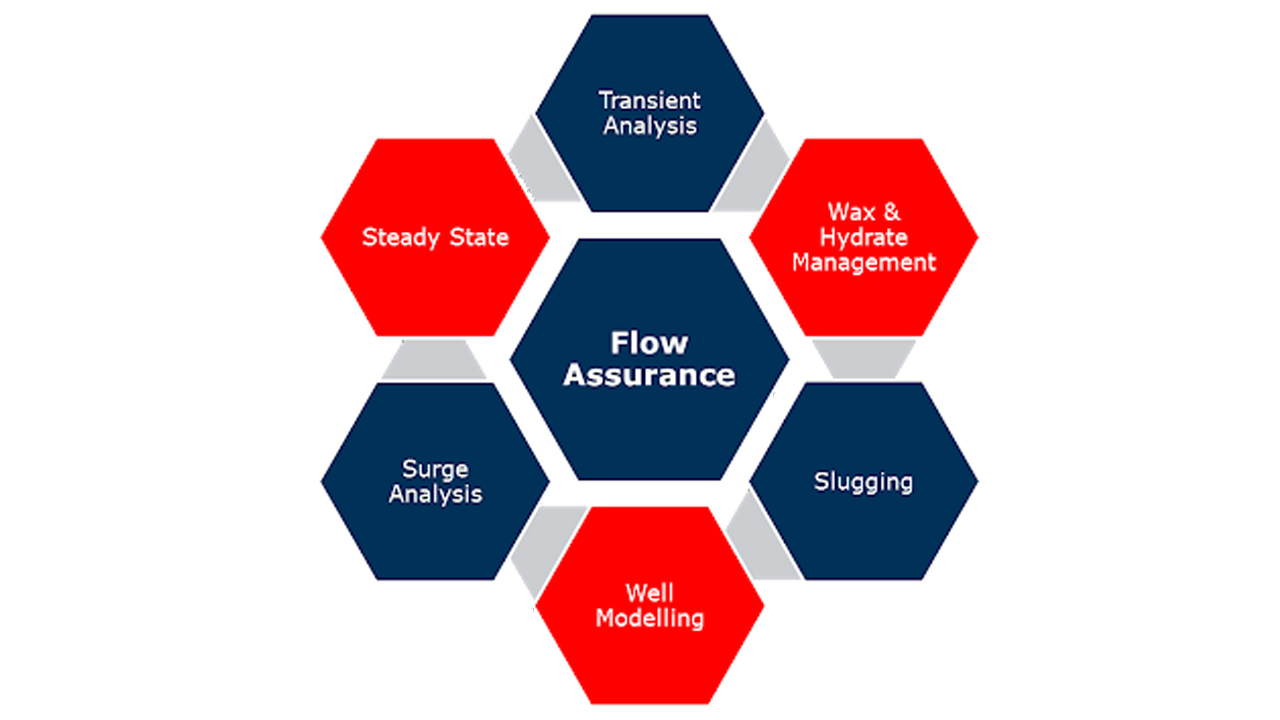

We have extensive expertise in Flow Assurance and Process Design of Subsea and onshore pipelines. This includes:

- Steady-state and transient analysis of single-phase and multiphase flow

- Hydrate and wax management study

- Surge analysis

- Slugging

- Well Modelling

- Pumping and compressing unit design and optimisation

Flow Assurance

SK Eng. has the capability to perform flow assurance and process design of subsea and onshore pipelines. We have extensive experience in flow assurance of multiphase production fluid starting from the reservoir, through the production tubing, Xmas Tree, Choke and subsea pipeline up to the subsea or onshore processing facilities. We also specialise in single phase oil, Liquefied Petroleum Gas (LPG) and natural gas flow assurance. We have long experience in the hydraulics of special petroleum products like Aviation Turbine Fuel, which need special treatment.

Our areas of expertise are shown below.

Multiphase Flow Assurance

Production Fluid comes out of the reservoir as a mixture of oil, gas, water and sludge. Pipeline transportation of the fluid poses flow assurance challenges. Based on the composition of the fluid, its reservoir pressure and temperature, and the ambient temperature of the environment in which the pipeline is laid, several challenges may arise. We engineer the system to make sure that un-interrupted production takes place and at desired arrival condition.

As part of multiphase flow assurance, steady state and transient analysis are performed.

Steady state Analysis

Steady state analysis is the first step towards understanding the overall behaviour of the transportation of the fluid, independent of time, after the flow has stabilized. As part of steady state analysis, pressure and temperature profile along the pipeline length is calculated. Flow rate turndown analysis is also performed.

Velocity of fluid is maintained below the erosional velocity calculated as per API RP 14E.

Transient Simulation

Transient simulation is time dependent. This analysis is performed to study the behavior of various flow assurance parameters during the transition between the start-up of the flow and steady state.

As part of the transient simulation, following analyses are performed:

- Start-up

- Shutdown

- Ramp-up and Ramp-down

- Joule-Thomson cooling

- Surge Analysis

Slugging Assessment

Slugging occurs in multiphase flow conditions as a result of the difference in velocity of liquid and gas phases (hydrodynamic slugging) and as a result of terrain conditions (terrain slugging). While the liquid phase flows in the lower section of the pipe, the gas phase being lighter flows on the upper section of the pipe. As a result of skin friction between the two layers, liquid moves and gets accumulated at the lower section of the pipeline, for example at the bottom of the riser and lower sections of spool pieces. Intermittently, a large liquid volume arrives at the separator, which may result in severe vibration of the riser or spools. To accommodate the large liquid volume at the separator, slug catcher is required to be designed.

We perform the slugging simulation and calculate the slug density and slug volume, which is used to calculate the force on the riser or sections of the spool. Volume of the slug catcher is also calculated.

We can also perform slug tracking in which a visual representation of course of movement of slug is simulated.

Software used

Software used for slugging is Pipesim, OLGA Core and Slug tracking Module of OLGA.

Pigging

In pigging simulation, pigging velocity and slug volume calculated as a result of pigging is calculated. Pigging simulation is performed by OLGA or Pipesim.

Hydrate Management

Hydrates are crystalline structures of water and natural gas, which form at high pressure and low temperature.

If the temperature of the fluid in the pipeline goes below the hydrate formation temperature, hydrate plug could form in the pipeline leading to blockage and consequently production loss. We adopt two-pronged approach of hydrate management as below:

- Hydrate formation avoidance

- Hydrate Inhibition

Hydrate Formation avoidance

In this approach, we make sure that that the fluid temperature is maintained above the hydrate formation temperature along the pipeline. We perform flow assurance modelling and recommend appropriate level of insulation, flow rate etc. to make sure that the temperature of the fluid is maintained above the hydrate formation temperature.

Softwares used

We use industry standard softwares like OLGA-Hydrate, Pipesim in association with Multiflash Hydrate or DELFI to perform this simulation.

Hydrate Inhibition

In case of hydrate formation cannot be avoided, we adopt an alternative approach by which hydrates molecules formed are not allowed to grow. This is achieved by hydrate inhibition: There are three techniques of hydrates inhibition as given below.

- Environmental inhibitors

- Thermodynamic inhibitors

- Kinetic inhibitors

In environmental inhibition, the production fluid is dried before it cools down by alcohol or silica gel or by adsorption of hygroscopic salt. Water is also removed by heating the production fluid and condensation subsequently.

Thermodynamic inhibition is achieved by

- Reducing the pressure of the gas

- Injecting salt solutions

- Injecting glycols/alcohols

We perform calculation of dosage rate of glycols/alcohols/salts.

Typically, the glycol used is Mono Ethylene Glycol (MEG), and the typical alcohol used is Methanol.

Kinetic Inhibition

In Kinetic hydrate inhibition, LDHI (Low Dosage Hydrate Inhibitors are used to stop agglomeration of hydrates. LDHI are typically polymers and copolymers. In this technique, rate of hydrate formation is reduced such that hydrate is not formed by the time the fluid reaches the destination. This method is not effective in case the fluid remains in the pipeline under stagnant condition during prolonged shutdown or line packing condition.

We perform calculation of dosage rate of kinetic inhibitors.

Wax Management

We perform wax formation study to calculate potential for wax formation and deposition in the pipeline. As an outcome of this study, recommendations are made on insulation requirement for the pipeline such that fluid’s temperature does not go below Wax Appearance Temperature (WAT) along the pipeline. If this can not be achieved by insulation of the pipeline, several other techniques could be recommended such as

- Dilution of the fluid in case of onshore pipeline

- Use of wax inhibitors (like Pour Point Depressants)

- Use of electrical heating systems

We perform calculation of dosage rate of kinetic inhibitors.

We also perform calculation of thickness of wax deposited on the inner wall of the pipeline.

Softwares Used

- OLGA Wax

- Pipesim

- Multiflash Wax

We perform calculation of dosage rate of kinetic inhibitors.

Softwares

There are many commercially available softwares popularly used in the oil and gas industry as given below.

| Software | Capability |

|---|---|

| Pipesim | Steday state, single phase and multi-phase flow assurance |

| Olga | Steday State and transient, single phase and multiphase flow assurance |

| Pipeline Studio (TLNET/ TGNET) | Single Phase steady state and transient Oil and Gas pipeline flow assurance |

| Maximus | Life Cycle Management Software |

| Flowmaster | Flow Assurance Software |

| DELFI | DELFI is a web-based environment, which includes Pipesim and OLGA and all its associated packages. This feature has been recently launched by Schlumberger in which the access to unlimited use of Pipesim and its associated suit of software is provided to the user based on a committed monthly or yearly subscription. Use of OLGA and its associated packages is provided on an hourly simulation based payment. The advent of DELFI has made more cost effective access to the Pipesim and OLGA packages, which was otherwise prohibitively expensive. We at SK Eng. make are keen to help our clients perform flow assurance studies with industry recognized softwares at reasonable. |

Past Projects

1. Urugua-Mexilhao pipeline project, Client Saipem, UK Limited

We performed steady-state and transient flow assurance of the deepwater Urugua-Mexilhao Pipeline Project located off Brazil’s coast.

2. Huntington Field Development Project, Client: EON Ruhrgas UK Northsea Limited

We performed steady-state and transient flow assurance of production, gas export, oil export, water injection and gas lift pipelines located in the North Sea between the UK and Norway.

3. Amukpe Escravos Pipeline Project, Client: Fenog Nigeria Limited

We performed steady-state and transient flow assurance of 20”/16” onshore oil pipeline located in the Warri Delta State of Nigeria. The project was extremely challenging as the pipeline was laid underground by Horizontal Directional Drilling to protect it from vandalism.

4. Scolty-Crathes Pipeline Remediation Project, Flow Assurance Verification for Bureau Veritas, Client:EnQuest Heather Ltd. Enquest Heather Limited decided to install a new pipeline to replace an existing pipeline which suffered from wax deposition and subsequent loss of production. We performed review and verification of flow assurance work performed by Genesis and Wood.

5. Dalia Phase III Pipeline project Verification. We performed verification of flowline and jumper flow assurance design.